Road Alerts

Challenges

Opportunities

Road Issues Identification

Road issues identification

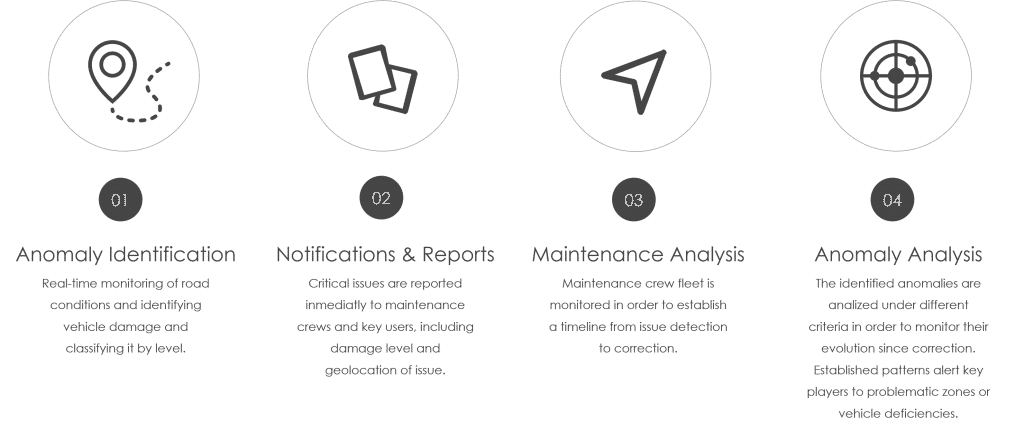

Issues on the road are detected using sensors on trucks or custom hardware. Damage is classified in order to prioritize maintenance.

Maintenance monitoring

Maintenance monitoring

Maintenance equipment is monitored in real time, and a timeline is established from the detection of an issue to its correction.

Pattern analysis

Pattern analysis

Recurring zones are identified and specific patterns in roads are detected to give feedback to planning engineers about which roads needs redesign or improvement.

Alerts & Reporting

Alerts & Reporting

Real-time alerts are dispatched to maintenance crews if specific damage patterns develop. Reporting dashboard and tools provide clear insights on road damage and maintenance evolution.

How does it work?